Gain Control & Accelerate Growth

Run your business with greater accuracy, transparency, and confidence.

Unify Operations

Eliminate disconnected spreadsheets, emails, and manual processes with one integrated system.

Improve Visibility

Gain insight into your inventory movement, spending activity, and revenue flow in one accessible place.

Ensure Data Accuracy

Automated workflows and validations minimize mistakes and duplicate entry reducing manual work.

Enhance Collaboration

Purchasing, production, sales, fulfillment, and billing teams all work from the same source of truth.

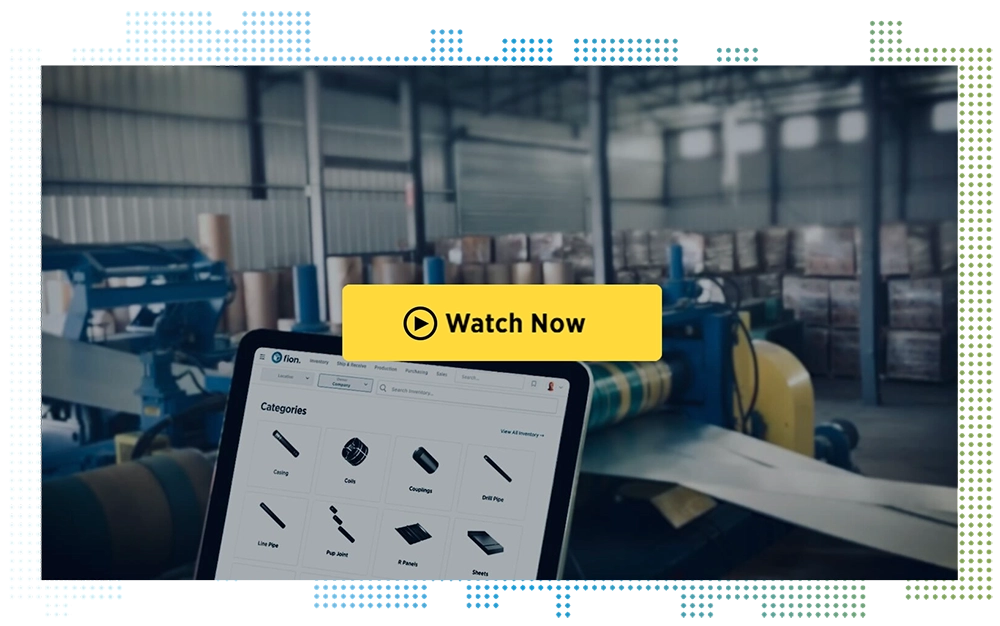

Core Operational Modules Designed for Steel & Metal Workflows

Replace operational complexity with clear, streamlined workflows.

Inventory

-

Real-Time Inventory Visibility

View live inventory status across all sites, including on-hand, available-to-promise, reserved, and WIP, using switchable item-level and rolled-up views for picking, planning, and decision-making.

-

Multi-Site & Third-Party Location Management

Manage inventory across internal sites, international operations, third-party facilities, processing plants, and storage locations with detailed sub-locations such as racks, bins, bays, and workstations.

-

Advanced Material Master with Standardized Attributes

Define material- and item-level attributes, categories, and specifications with a flexible Material Master that standardizes data across complex and commoditized products.

-

Advanced Search & Attribute-Based Filtering

Find inventory instantly using fast search across attributes, serial numbers, PO numbers, locations, ownership, condition, and usage status for precise and flexible results.

-

Barcode-Driven Inventory Operations

Use barcode scanning for receiving, put-away, picking, rack/bin identification, cycle counts, and reconciliation to streamline every stage of inventory movement.

-

Cycle Counts & Inventory Reconciliation

Perform guided cycle counts and full inventory reconciliations with discrepancy detection, on-site scanning, and structured resolution workflows.

-

Complete Item Lifecycle & Cost History

Track every event in an item's lifecycle, including initial receipt, processing, shipments, returns, and billing, along with full cost history such as purchase cost, freight, and service charges.

Purchasing

-

Comprehensive Purchase Order Management

Create, duplicate, and manage purchase orders with accurate costing tied to materials, quantities, services, and expected receipts.

-

Electronic Purchase Order Approvals

Send purchase orders for electronic approval with secure, auditable confirmations to streamline authorization.

-

AP Vouchering for Materials & Services

Voucher material receipts, freight charges, and processing services while preventing double payments, tracking outstanding vendor charges, and managing prepaid materials or services.

-

Pre-Receiving & Advanced Shipping Notifications

Pre-load inbound shipments using manifests or ASNs for fast, barcode-driven receiving and improved accuracy.

-

Consignment Inventory & Withdrawal Tracking

Track vendor-consigned inventory, issue withdrawals for billing, and monitor consignment status, usage, and expiration dates.

-

Vendor Master & Supplier Management

Manage all suppliers, processors, freight carriers, and service vendors through a centralized Vendor Master.

-

Cost Tracking Across Receipts & Services

Track costs for material receipts, non-PO receipts, freight, and processing services with clear visibility into item-level and service-level cost accumulation.

Production

-

Production Scheduling & Work Order Management

Plan and manage production with schedule-driven work orders that track all inputs, outputs, and real-time WIP across internal and third-party facilities.

-

Task Templates, Work Centers & Work Group Management

Use configurable task templates to define production steps and manage work centers and work groups such as slitting, heat treat, threading, painting, or coating with precise task assignments and time tracking.

-

Automated Routing & Work Center Boards

Automate the routing of tasks between work groups and provide each team with real-time boards to start, complete, and hand off work, ensuring smooth flow and accurate production tracking.

-

Bill of Materials (BOM) Management

Define Bills of Material for finished goods, including required components, setups, and production steps needed to execute each job with accuracy.

-

Tracking & Traceability

Track the full history of every item used in production including origin, material test reports (MTRs), compliance requirements, and cost consumption to support quality, auditability, and customer documentation.

-

Third-Party Processing & Service Tracking

Coordinate third-party production work by managing outsourced tasks, tracking service completion, and capturing all related charges for accurate costing and billing.

-

Production Requests for Customer Material

Manage production requests for customer-supplied materials, enabling service-based processing workflows and visibility into customer order status.

Sales

-

Sales Order Management & Fast Picking

Manage sales orders with fast picking workflows, coordinated fulfillment scheduling, and real-time tracking of when items are ready to bill.

-

Quote Creation, Sales Rep Tracking & Mobile Quoting

Build quotes with accurate pricing from desktop or mobile, track sales reps for commission accountability, and convert quotes directly into sales orders.

-

Fulfillment Scheduling, Staging & Delivery Coordination

Schedule picking and staging operations, coordinate customer pickup, in-house shipping, or third-party freight, and track all outbound deliveries from a single workflow.

-

Centralized Billing & Invoice Delivery

Generate invoices directly from sales activity with support for tax exemption rules, bill-to and ship-to preferences, AP contact settings, and electronic invoice delivery or accounting system sync.

-

Customer Master & Account Profiles

Maintain detailed customer profiles including bill-to and ship-to details, tax status, contact information, payment terms, account notes, and parent or child customer relationships.

-

Credit Memos & Customer Returns

Issue credit memos for full invoices or individual lines, create ad-hoc credits, and process customer returns with full visibility into adjustments and review workflows.

-

Order Notifications & Team Alerts

Automatically notify sales, fulfillment, and operations teams of new orders, revisions, and significant changes to support fast decision-making and workflow coordination.

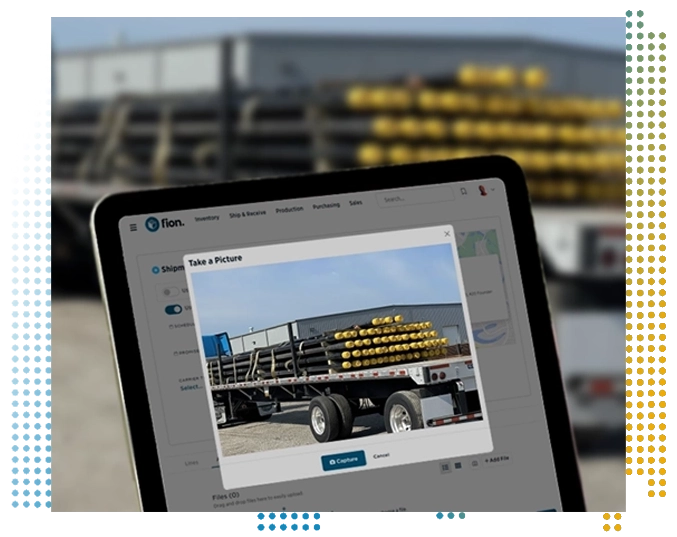

Smart Logistics Management

Coordinate every shipping and receiving workflow from a centralized logistics hub. Fion streamlines the movement of material across your entire operation, whether you are shipping, transferring, or receiving goods.

Key capabilities include:

- Multi-shipment scheduling through shipping jobs

- Mobile sign-offs with photos and electronic signatures

- Support for customer shipments, internal transfers, third-party processing, consignment receipts, and vendor deliveries

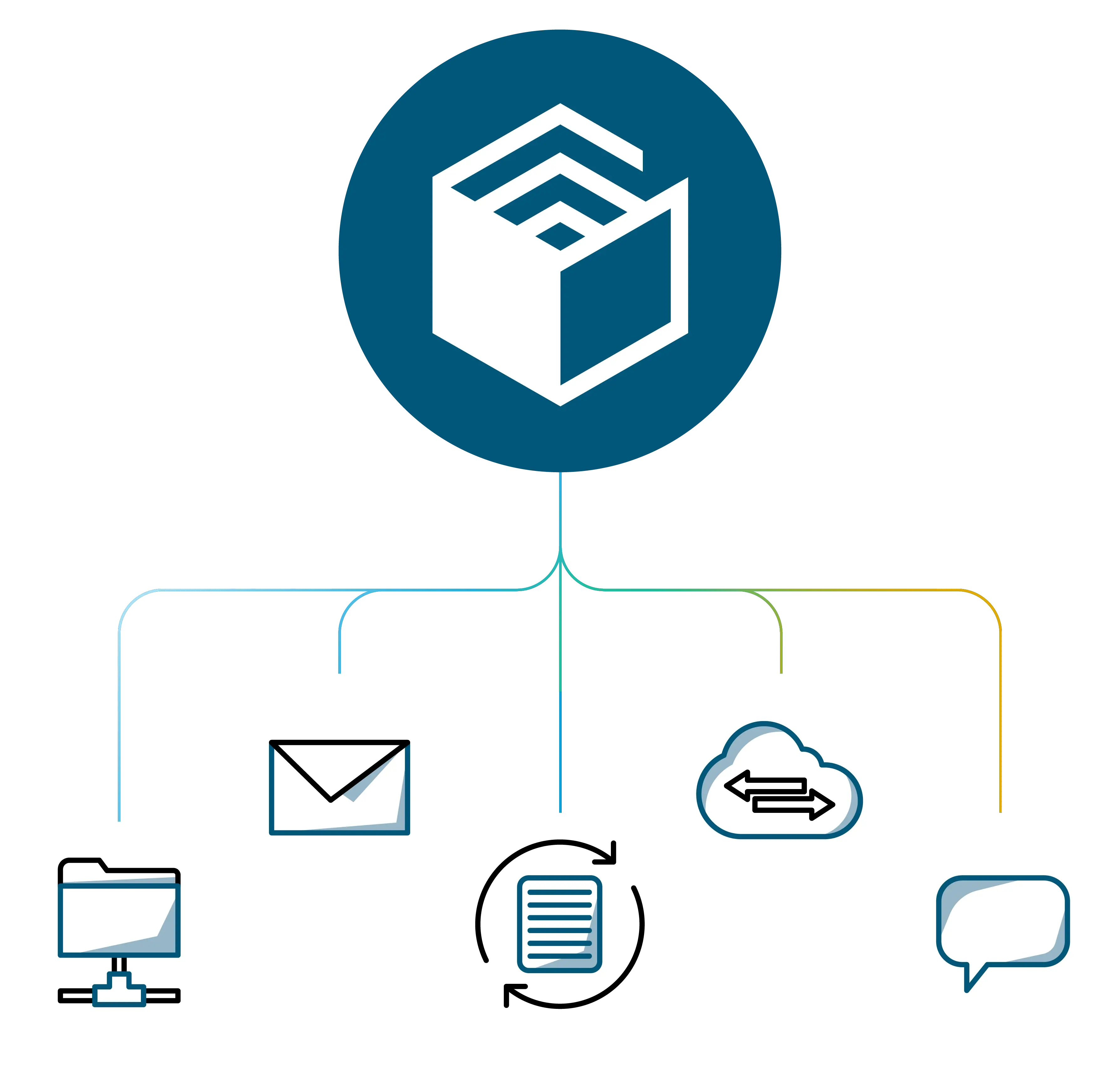

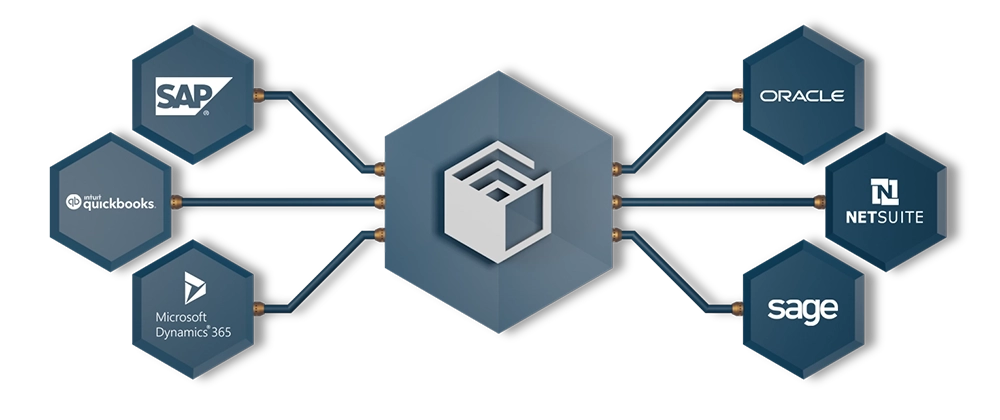

Seamless Accounting and Systems Integration

Integrate with accounting systems like QuickBooks, Microsoft Dynamics, NetSuite, or Sage through automated batch syncs for accurate financial reporting. Fion can connect to other applications through flexible data exchange options.

Key integrations include:

- Batch-based accounting syncs for key financial data

- Ability to connect to your existing CRM, line-of-business, and sales tax applications

- Supports common data exchanges such as API, EDI, and FTP

Built for Steel, Metal, and Value-Add Processing Industries

Built to support a broad range of steel and metal products including wire, cable, drilling tools, and value-add operations, while specializing in coils, sheets, and pipe & tube.

Coils, Sheets, & Panels

- Supports coil processing workflows including slitting, cut-to-length, coating, and roll forming.

- Enables pre-receiving of shipments, with fast barcode receiving when material arrives.

- Provides full traceability of inventory back to master coils for quality, compliance, and costing.

- Automatically links all master and processed items to the correct Material Test Reports (MTRs).

Pipe & Tubing

- Supports pipe and tube processing workflows including heat treat, thread and upset, buck-on/buck-off, and lining.

- Enables multi-quantity batch tracking for pipe to ensure accurate traceability and costing.

- Tracks any inventory item back to its original purchase for quality, compliance, and costing purposes.

- Automatically links all inventory to the correct Material Test Reports (MTRs).

Leverage Technology that Scales

Hassle-Free, Cloud-Native Infrastructure